How AI is revolutionizing the packaging industry in 2025

E-commerce has exploded in recent years, with more people shopping online than ever before. This shift has created new demands on how products are...

5 min read

Ekaterina Skalatskaia

:

Updated on June 26, 2025

Ekaterina Skalatskaia

:

Updated on June 26, 2025

In today's highly competitive market, packaging design is not just about creative flair—it's a critical operational process that can influence brand perception, speed to market, and overall profitability. Yet, many organizations still manage packaging workflows without the benefit of clear performance data.

To truly optimize your packaging design process, it's essential to track the right metrics—those that provide visibility into performance, identify bottlenecks, and drive continuous improvement.

Here are the top metrics every packaging team should track and monitor, and why they are essential.

What to Measure:

Number of artworks delivered over time

Delivery trends by project, brand, or product category

Why It Matters:

Tracking artwork delivery rates helps you understand team productivity and workflow efficiency. Consistent delivery rates reflect stable operations, while sudden drops may indicate resource shortages or process bottlenecks. Recognizing these patterns early allows better capacity planning and resource allocation.

What to Measure:

Percentage of artworks approved without revisions

Why It Matters:

High first-time approval rates mean your briefs are clear, collaboration is effective, and review expectations are well-aligned. Improving this metric reduces the number of review cycles, saving time and cost while boosting team morale and client satisfaction.

What to Measure:

Number and percentage of artworks rejected during the approval process

Common reasons for rejections

Why It Matters:

Frequent rejections slow down the entire packaging lifecycle. Tracking rejection rates—and the reasons behind them—helps identify systemic issues such as poor briefs, inconsistent feedback, or skill gaps. Reducing rejections minimizes rework, costs, and time-to-market delays.

What to Measure:

Percentage of projects completed on or before their deadlines

Why It Matters:

On-time delivery is crucial for launching products and meeting market demand windows. Late packaging approvals can derail marketing campaigns and lead to missed sales opportunities. Monitoring this KPI ensures the team stays accountable and highlights any consistent timeline issues.

What to Measure:

Average time from artwork submission to final approval

Why It Matters:

Extended review cycles are a hidden drain on timelines. Tracking this KPI helps identify slowdowns in the feedback process and uncovers opportunities to streamline communication between stakeholders, accelerating approvals and reducing project lead times.

What to Measure:

Total number of active projects at any given time

Average project duration

Why It Matters:

A backlog of open projects can overwhelm teams and dilute focus. Tracking open projects ensures that workloads are balanced, and helps managers identify when teams are at or over capacity. It also supports better priority setting across departments.

What to Measure:

Time stakeholders take to provide feedback after artwork submission

Why It Matters:

Slow stakeholder response is a major bottleneck in packaging workflows. Measuring response times holds reviewers accountable and highlights the need for process training or workflow automation.

What to Measure:

Percentage of project briefs submitted with all required information

Why It Matters:

Incomplete briefs lead to confusion, rework, and wasted time. By tracking brief completeness, organizations can raise the standard of inputs, which directly improves creative output quality and approval speed.

We're here to help. Get in touch with our team and discover how Cway can streamline your artwork approvals and project management.

In the modern marketplace, packaging serves as more than just a protective layer — it is a powerful extension of brand identity and a key factor in the consumer decision-making process. As companies strive to differentiate themselves, speed to market has become a strategic imperative. Launching products faster enables brands to stay ahead of trends, respond to consumer demands, and outpace competitors.

However, achieving faster time-to-market without sacrificing quality or compliance is not simple. The packaging design process involves multiple touchpoints: creative teams, marketing, regulatory review, supply chain logistics, and more. Each handoff introduces potential delays and risks if not properly managed.

This is where tracking the right KPIs becomes crucial.

By embedding a data-driven approach into packaging workflows, organizations can:

Without visibility into where bottlenecks occur — whether it’s creative development, stakeholder review, or approval stages — delays can snowball quickly, often becoming visible only when deadlines are missed. KPIs like average review time or stakeholder response time spotlight these hidden inefficiencies early, giving teams a chance to intervene, reallocate resources, or streamline approvals before minor slowdowns turn into major setbacks.

Understanding trends in project volumes, artwork delivery rates, and revision cycles allows organizations to predict future workload surges. Accurate forecasting ensures that teams are neither overwhelmed nor underutilized, leading to better resource allocation, balanced workloads, and more realistic project timelines. This not only improves operational efficiency but also helps prevent burnout and quality dips caused by resource strain.

Errors late in the design or approval process are particularly costly, often leading to production delays, regulatory risks, or rushed reprints. KPIs such as first-time approval rates and rejection rates help identify patterns of recurring mistakes — whether due to incomplete briefs, unclear feedback, or process gaps. By analyzing these metrics, teams can implement targeted improvements to minimize rework and maintain high quality standards throughout the project lifecycle.

Packaging projects often involve cross-functional teams — from creative designers to legal reviewers, marketing managers to supply chain coordinators. Each has different priorities and timelines. Metrics like average stakeholder response time and brief completeness rates foster better accountability and transparency. Clear, measurable insights promote a culture of collaboration, ensuring that all departments are aligned and working toward the same market launch goals.

Consumer preferences and market trends shift rapidly. Brands that can respond faster gain a competitive edge. By continuously monitoring KPIs, companies can accelerate packaging timelines without compromising on quality or compliance. This agility allows businesses to launch products in sync with trends, seize emerging opportunities, and avoid the high costs of missed market windows.

Ultimately, tracking and optimizing KPIs transforms the packaging design process from a traditional bottleneck into a strategic enabler. With real-time insights and actionable data, packaging teams can move beyond reactive problem-solving to proactive optimization — continuously improving speed, quality, and efficiency.

A data-driven packaging operation isn’t just more efficient; it’s more competitive, more resilient, and more aligned with broader business objectives. In a world where first to shelf often means first to win, mastering packaging KPIs isn’t optional — it’s a core strategy for growth.

Experience the power of smart packaging workflow analytics. Start your free trial and take control of your projects today.

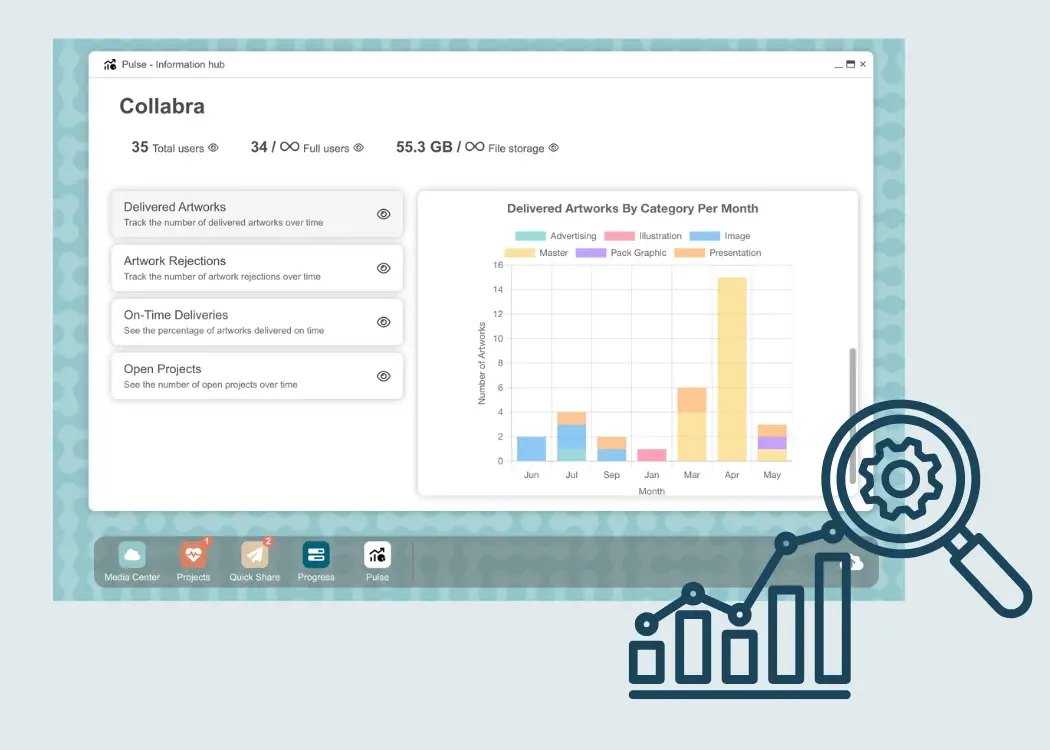

Turning operational data into actionable insights is the key to optimizing modern packaging workflows — and this is exactly what Cway Pulse is designed to deliver. Pulse is Cway’s brand-new analytics and informational hub, built to give teams full visibility into their packaging and artwork management processes.

Whether you're managing complex artwork approvals, juggling tight project deadlines, or collaborating with multiple cross-functional teams, Pulse helps you stay ahead with dynamic, data-driven insights.

Here’s how Pulse empowers packaging and creative teams:

Pulse transforms your operational data into a clear, interactive experience. With real-time statistics, trend visualizations, and dynamic graphs, teams can instantly understand how their workflows are performing. From identifying workflow bottlenecks to celebrating efficiency gains, Pulse provides the tools you need to make informed decisions with confidence — all at a glance.

Pulse serves as a command center for performance tracking and workflow analysis. Instead of scattered reports or manual tracking, everything you need is centralized and easy to access, providing a complete overview of your operational health.

By consolidating critical metrics and delivering powerful visualizations, Pulse transforms complex data into clear, actionable insights — giving packaging and creative teams the tools they need to optimize workflows, boost productivity, and speed up time-to-market.

E-commerce has exploded in recent years, with more people shopping online than ever before. This shift has created new demands on how products are...

As creative teams expand, product lines diversify, and compliance requirements tighten, managing design assets has never been more complex. Artwork...

Packaging management software helps teams control packaging artwork, approvals, and production files in one centralized system. For brands working...