The role of prepress collaboration software in packaging design

The prepress process plays a critical role in ensuring high-quality packaging production. But with multiple stakeholders involved — including...

In packaging design, color accuracy is more than an aesthetic choice — it’s a reflection of your brand’s identity and consistency. Whether you’re printing thousands of cartons, sleeves, or labels, each one needs to look identical on the shelf. This is where color separation becomes essential.

Color separation is the prepress process of dividing a digital artwork into individual color layers so that each one can be printed separately. These layers — typically Cyan, Magenta, Yellow, and Black (CMYK) — are combined during printing to reproduce the complete image.

In some cases, spot colors (like Pantone inks) are used for brand elements that need exact tone reproduction, such as a logo or background color. Each separation corresponds to a specific printing plate or cylinder, which applies its color layer in perfect alignment with the others.

CMYK (Process Color Separation)

This standard method uses four colors that blend to create the full image. It’s ideal for photographic or detailed designs.

Spot Color Separation

Each ink is mixed and printed separately — commonly used for corporate colors or metallic and fluorescent inks that can’t be replicated with CMYK.

Hybrid Separation

Many packaging projects use both CMYK for imagery and spot colors for logos or key brand elements.

Brand Consistency Across Print Runs

Correct separations ensure that your signature red or blue looks the same on every batch and every product line.

Prevents Expensive Printing Errors

Misregistration or overlapping colors can ruin a print job. Proper separations ensure each layer aligns precisely.

Optimized for Printing Techniques

Different print methods — flexographic, offset, gravure, or digital — require tailored separations for best results.

Supports Sustainability and Efficiency

Streamlined separations can reduce ink waste and reprints, supporting both environmental and cost goals.

Always design in CMYK color mode, not RGB.

Use Pantone libraries for defined brand colors.

Collaborate early with prepress and print suppliers to understand limitations.

Use digital proofing tools to review separations before production.

Manage artwork versions and approvals centrally to avoid outdated files going to print.

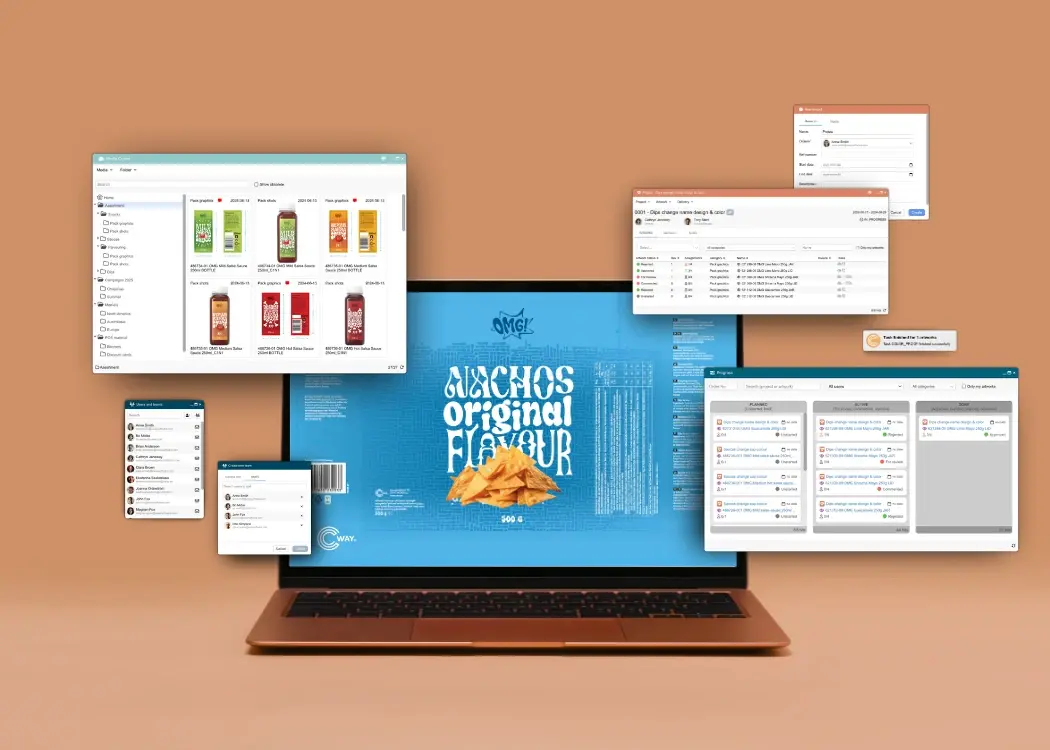

Platforms like Cway software simplify artwork approval and version control, ensuring teams deliver print-ready files with accurate separations every time. From proofing to final approval, automated workflows help eliminate errors and maintain brand consistency — no matter how many stakeholders or markets are involved.

Color separation is the process of dividing a design into individual color components — typically Cyan, Magenta, Yellow, and Black (CMYK) — so that each can be printed separately. When combined, these layers reproduce the full-color image with precision and consistency.

Accurate color separation ensures that brand colors stay consistent across all packaging materials and print runs. It also helps avoid costly printing errors such as misregistration, color shifts, or poor image quality.

Lorem ipsum dolor amet aesthetic photo booth activated charcoal occupy iPhone schlitz squid. CMYK (process colors) uses four inks blended together to produce a full spectrum of colors, while spot colors (like Pantone inks) are pre-mixed for exact hues. Spot colors are ideal for logos or brand elements that require precise color matching.

By maintaining accurate separations, packaging teams ensure that every product — regardless of where or how it’s printed — uses the same approved brand colors. This is vital for building a strong, cohesive shelf presence.

Typically, prepress teams or print suppliers handle color separation before production. However, designers and brand teams must provide properly prepared artwork files to avoid issues during printing.

Artwork management platforms like Cway software support packaging teams by streamlining artwork approval, color accuracy checks, and version control — ensuring every file that goes to print is color-accurate and production-ready.

The prepress process plays a critical role in ensuring high-quality packaging production. But with multiple stakeholders involved — including...

Brand consistency is what makes a product instantly recognizable and trustworthy. From packaging design to marketing materials, every detail shapes...

Managing packaging artwork isn’t just about design — it’s a complex process involving briefs, reviews, approvals, and strict compliance. In this...