How to build a compliant and scalable approval workflow

Creating packaging isn’t just about great design—it’s about building an approval workflow that ensures every step, from concept to shelf, is aligned,...

4 min read

Ekaterina Skalatskaia

:

Updated on August 13, 2025

Ekaterina Skalatskaia

:

Updated on August 13, 2025

The packaging artwork approval process is crucial for any brand aiming to launch products quickly and effectively. However, even minor mistakes in this process can cause significant delays, increased costs, or even legal complications. This article will outline five common packaging artwork approval mistakes and provide actionable tips to help brands avoid them, ensuring a smooth and efficient approval process.

One of the most common mistakes in the artwork approval process is poor communication between departments—particularly between design, marketing, and production teams. When teams aren't aligned, important details can be missed, leading to misinterpretations or even incorrect artwork submissions.

How to Avoid It:

Schedule regular check-ins to discuss progress, address concerns, and ensure alignment.

Encourage open feedback loops so everyone is on the same page throughout the process.

Another mistake many teams make is failing to properly track artwork versions. Without version control, it’s easy to approve outdated designs or overlook important changes made during the approval process. This can lead to confusion and errors, especially when multiple people are involved in the review.

How to Avoid It:

Implement version control systems or digital asset management (DAM) software that tracks every change to the artwork and ensures everyone works on the latest version.

Include clear labels (e.g., "Final Version," "Version 2") in file names to avoid confusion.

Set up a central repository where all artwork files are stored, ensuring easy access for all involved.

Cway Solution: Cway automatically tracks every version of an artwork, keeping a complete history of revisions. Users can view, compare, and restore previous versions, making sure that everyone is working with the most up-to-date design.

Sometimes, key stakeholders like legal teams, compliance officers, or senior managers are left out of the packaging approval process, leading to last-minute revisions or missed legal or regulatory requirements.

How to Avoid It:

Create a streamlined approval workflow that includes all relevant stakeholders from the outset.

Use design project management tools to keep track of everyone’s involvement and approval stages.

Make sure that compliance and legal reviews are built into the process to avoid last-minute rework.

Cway Solution: Cway’s workflow features enable easy routing of artwork to relevant stakeholders at the right stage of the process. With customizable approval paths and automated notifications, you can ensure that every necessary party reviews the artwork on time.

Having too many approval stages or excessive back-and-forth can unnecessarily delay the packaging approval process. The more steps there are, the more opportunities there are for mistakes or lost information.

How to Avoid It:

Simplify the approval process by reducing unnecessary stages and making approval stages more efficient.

Use digital proofing tools to speed up the review process, enabling teams to mark up files with comments and approve changes in real-time.

Create predefined checklists or approval criteria to ensure that each team knows what to expect and can make faster decisions.

Cway Solution: Cway optimizes the approval workflow by allowing users to set predefined approval stages and automate approvals. With real-time tracking and digital proofing tools, the process is streamlined, ensuring faster sign-offs and fewer delays.

Ignoring or neglecting compliance and regulatory standards for packaging can lead to costly mistakes and legal issues, especially for industries such as food and pharmaceuticals, where labeling requirements are strict and vary by region.

How to Avoid It:

Work closely with your legal and compliance teams to review artwork before it reaches the approval stage.

Use automated tools that check for compliance issues (such as font size or ingredient listing) to catch potential mistakes early.

Cway Solution: Cway provides a collaborative platform that streamlines the artwork approval process by enabling seamless communication between design, marketing, legal, and compliance teams. It helps ensure all stakeholders are involved at the right stages, reducing the risk of missing regulatory requirements. With Cway’s easy-to-use version control and workflow management tools, you can ensure your artwork is reviewed thoroughly before reaching final approval, minimizing the risk of non-compliance.

The packaging artwork approval process doesn't have to be riddled with mistakes and delays. By avoiding the common pitfalls outlined above—poor communication, lack of version control, missing stakeholders, overcomplicated workflows, and compliance neglect—you can streamline the approval process, reduce errors, and ensure a faster time-to-market for your products.

The most common mistake is poor communication between teams. Without clear communication, important details can be missed, leading to misinterpretations and errors. It’s essential to keep all departments aligned through regular meetings and collaboration tools.

To speed up the process, simplify your approval stages, implement version control, and ensure all stakeholders are involved early. Using digital proofing tools and automating where possible can also reduce delays and help teams make decisions faster.

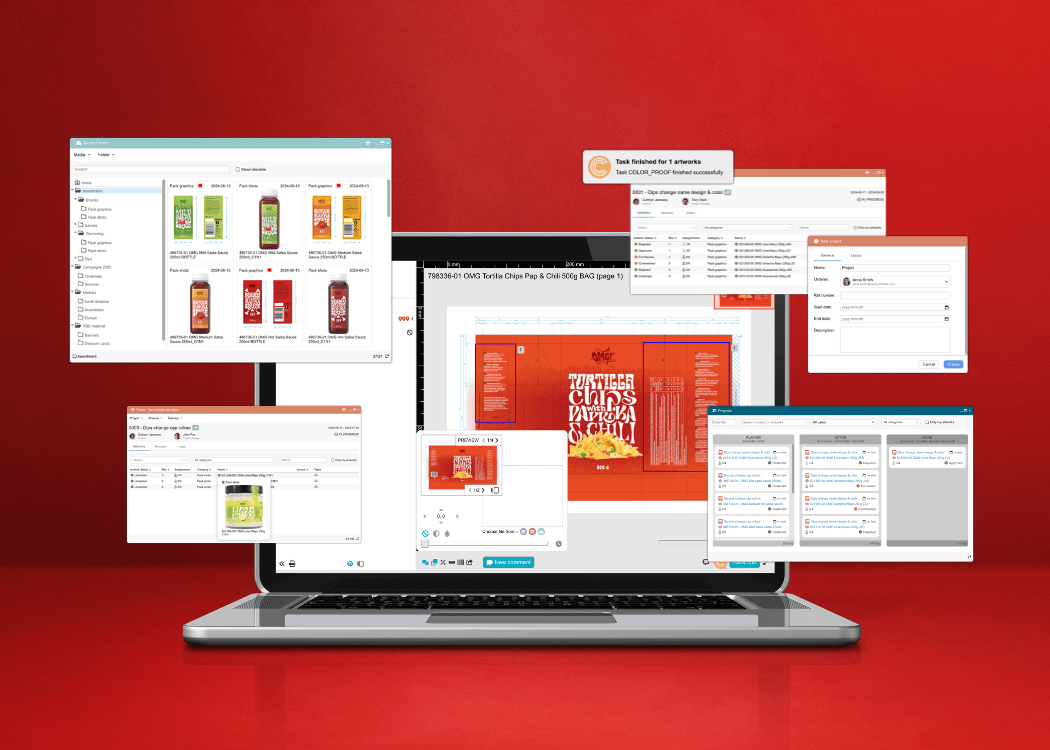

Cway simplifies the artwork approval process by providing a centralized platform for collaboration, real-time feedback, and version control. It ensures that all relevant teams are involved at the right stages, streamlining communication and reducing the risk of errors.

Version control ensures that everyone is working on the most up-to-date artwork, preventing errors from outdated designs. It tracks changes made throughout the approval process, providing a complete history of revisions for easier review and comparison.

By using workflow management tools like Cway, you can create automated approval paths that involve all necessary stakeholders at the right time. This ensures that the relevant teams—such as design, legal, marketing, and compliance—review the artwork before it reaches final approval.

Creating packaging isn’t just about great design—it’s about building an approval workflow that ensures every step, from concept to shelf, is aligned,...

When it comes to managing packaging artwork, businesses in the food, consumer packaged goods (CPG), and pharmaceutical industries face the challenge...

Streamline design approvals, enhance feedback loops, and get to market faster with Cway®—your all-in-one platform for artwork approval process.