How approval tools help packaging teams work smarter

In this article, we explore why packaging teams need specialized brand content approval tools. From faster reviews to better collaboration, we’ll...

4 min read

Ekaterina Skalatskaia

:

Updated on January 13, 2026

Ekaterina Skalatskaia

:

Updated on January 13, 2026

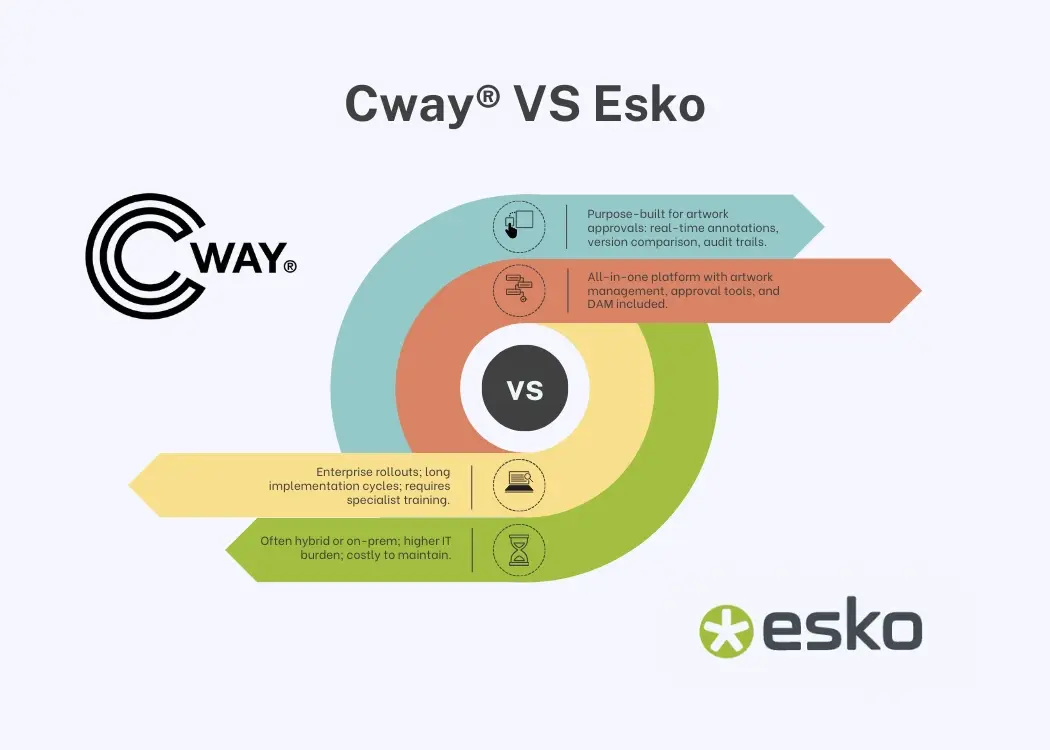

For many FMCG teams, the real challenge isn’t structural design or prepress—it’s coordinating approvals across marketing, legal, QA, and external agencies without slowing down launches. If you’re searching for Esko alternatives, you’re likely evaluating how to simplify artwork management without sacrificing control or compliance. Esko is a powerful enterprise platform, widely used in packaging and graphic arts, but for many FMCG teams it comes with long onboarding times, complex workflows, and high total cost of ownership.

In this comparison of Cway® vs. Esko, we look at how a lightweight, cloud-native artwork management system compares to a traditional enterprise solution. You’ll see the key differences in artwork approval workflows, collaboration, usability, and cost—and why many packaging teams consider Cway one of the best Esko alternatives for managing artwork and packaging approvals efficiently.

In the packaging industry, Esko has long been considered the default choice for enterprise packaging software. With decades of development, its tools cover nearly every aspect of packaging — from structural CAD and dieline creation to prepress, 3D visualization, workflow automation, and quality control.

But not every packaging team needs that full stack. In fact, for fast-moving consumer goods (FMCG) companies, the day-to-day bottleneck is rarely CAD engineering or complex prepress work. It’s the artwork approval cycle — managing stakeholders, ensuring compliance, keeping versions under control, and getting packs approved fast enough to launch.

That’s why more brands are searching for Esko alternatives: tools that are lighter, faster, easier to use, and designed for modern, cloud-based collaboration.

Cway® is one of those alternatives. While Esko represents the heavyweight, enterprise-class solution, Cway focuses on simplicity, speed, and usability — delivering exactly what FMCG packaging teams need without the overhead of a large enterprise system.

Esko’s reputation is built on its breadth of capabilities. For companies managing packaging design end-to-end in-house, Esko provides unmatched depth in areas such as:

Structural Design (ArtiosCAD) – Creating dielines, resizable packaging templates, and structural prototypes.

Prepress & Color Management – PDF editing, trapping, proofing, and ensuring files are truly print-ready.

3D Visualization – Virtual mockups, shrink-sleeve simulations, shelf visualization, and photorealistic packshots.

Workflow Automation (WebCenter, Automation Engine) – Complex workflows spanning design, prepress, and compliance across multiple sites.

These tools are extremely powerful, but they come at a cost:

Complexity: Esko requires training, specialist staff, and significant IT support.

Deployment time: Implementations can take months, sometimes longer for large organizations.

High TCO: Beyond licensing, companies pay for infrastructure, consulting, upgrades, and ongoing support.

Steep learning curve: Non-technical stakeholders (brand managers, legal, QA) often find Esko intimidating.

For global enterprises with in-house packaging engineering teams, Esko is a natural fit. But for FMCG brands focused on speed, agility, and collaboration, Esko can feel like too much software for the job.

When Esko Still Makes Sense:

In-house packaging engineering teams

Heavy prepress and structural CAD needs

Long-term enterprise transformations

Through conversations with FMCG artwork managers, common themes emerge about what they seek in Esko alternatives:

Simplicity – A system that anyone can use without training: designers, marketers, legal, QA, and agencies.

Speed – Faster onboarding, quicker approval cycles, fewer bottlenecks.

Cloud-native collaboration – Seamless sharing across geographies, suppliers, and partners.

Lower TCO – Avoiding hidden costs from hardware, consulting, and specialist staff.

Focus – Tools designed specifically for artwork and approval workflows rather than the entire packaging stack.

This is the niche where Cway® delivers.

Below is a deeper look at how Cway and Esko compare across key dimensions:

|

Dimension |

Esko |

Cway® |

|---|---|---|

|

Typical users |

Packaging engineers, prepress specialists |

Brand managers, marketing, legal, QA, agencies |

|

Deployment & Onboarding |

Enterprise rollouts; long implementation cycles; requires specialist training. |

Cloud-native, fast to deploy, intuitive to use; teams up and running in days. |

|

Time to value |

Months (long implementation and adoption cycles) |

Days (immediate impact on approval workflows) |

|

User Experience |

Powerful but complex; designed for packaging engineers and prepress specialists. |

Modern, intuitive, and lightweight; built for collaboration among all stakeholders. |

|

Artwork Approval Workflow |

Embedded in broader systems; strong but often over-engineered for daily FMCG needs. |

Purpose-built for artwork approvals: real-time annotations, version comparison, audit trails. |

|

Collaboration |

Effective for enterprise but requires logins and training; less intuitive for occasional users. |

Browser-based access, minimal training, ideal for agencies, printers, and external partners. |

|

Artwork Management & DAM |

Requires separate tools: WebCenter for artwork management and MediaBeacon for DAM. |

All-in-one platform with artwork management, approval tools, and DAM included. |

|

Infrastructure |

Often hybrid or on-prem; higher IT burden; costly to maintain. |

100% cloud-native SaaS; low IT footprint, automatically updated. |

|

Flexibility |

Customizable, but heavy configuration and consulting required. |

Tailored FMCG workflows out-of-the-box; customization without overhead. |

|

3D Visualization & CAD |

Advanced tools for dielines, shrink sleeves, and 3D mockups. |

Focuses on artwork and packaging graphics, not structural CAD. |

|

Total Cost of Ownership (TCO) |

High: licenses, modules, IT support, infrastructure, training, and consulting. |

Lower: predictable subscription model, minimal hidden costs, faster ROI. |

The differences between Esko and Cway® are not just technical — they affect business outcomes:

Time-to-market: Cway’s simplified workflows cut approval cycles dramatically, helping FMCG teams launch seasonal SKUs, promotions, or regulatory updates faster.

Error reduction: With centralized versions, annotation tools, and audit trails, Cway reduces costly errors and reprints.

Stakeholder adoption: While Esko often requires training, Cway’s intuitive UI means legal, QA, and marketing teams adopt it quickly.

Cost savings: Avoiding enterprise infrastructure, consulting, and complex licensing means lower TCO and faster return on investment.

For FMCG teams handling hundreds of SKUs across multiple markets, these factors make a measurable difference in speed, cost, and competitive edge.

For FMCG brands, the biggest challenges are approval bottlenecks, version confusion, and speed-to-market.

This is exactly where Cway excels:

Lightweight and modern – cloud-native SaaS, always up-to-date, no heavy IT burden.

Intuitive and friendly – easy for everyone, not just packaging specialists.

Focused on artwork approvals – the true pain point for FMCG teams.

Faster ROI – lower costs, faster deployment, immediate impact on cycle time.

If your business requires full structural packaging engineering and advanced prepress workflows, Esko is still the industry standard. But if your biggest headaches are artwork approvals, stakeholder alignment, and speed-to-market, then Cway® is the right Esko alternative.

Cway helps packaging teams:

Cut approval time by up to 50%

Reduce costly errors and recalls

Launch products to market faster

Simplify collaboration across internal and external stakeholders

Cway is a strong Esko alternative for artwork management and approval workflows. While Esko focuses on the full packaging engineering stack, Cway is designed specifically to help FMCG teams manage artwork versions, approvals, and compliance faster — without enterprise complexity.

Compared to Esko, Cway offers much faster time to value. Most teams implement Cway within days, not months. As a cloud-native artwork management solution, it requires no heavy configuration or specialist training, making it a practical Esko workflow alternative for fast-moving teams.

Yes. Cway is built for regulated FMCG and pharma environments. It includes version control, audit trails, role-based access, and documented approvals — all essential features of compliant artwork management software.

Companies that look for alternatives to Esko software are often FMCG, food & beverage, pharma, and retail brands. These teams typically need faster artwork approvals, easier collaboration, and lower total cost of ownership than traditional enterprise Esko solutions provide.

Book a free demo today and see how Cway can simplify your artwork and packaging workflows:

In this article, we explore why packaging teams need specialized brand content approval tools. From faster reviews to better collaboration, we’ll...

As packaging projects grow more complex, choosing the right artwork management software can save countless hours and prevent costly design errors.Two...

As creative teams expand, product lines diversify, and compliance requirements tighten, managing design assets has never been more complex. Artwork...