Top 7 artwork management software for packaging teams (2026)

If you're part of a team that creates packaging—whether it’s for yoghurt tubs, medicine boxes, or shampoo bottles—you know how tricky it can be to...

5 min read

Ekaterina Skalatskaia

:

Updated on November 14, 2025

Ekaterina Skalatskaia

:

Updated on November 14, 2025

Choosing the right label software is key for businesses that depend on smooth and accurate labeling processes. As rules become stricter and supply chains more complex, the right label management tool helps keep your operations efficient, compliant, and flexible as needs change. This guide gives a clear and practical approach to finding the best label management software for your business.

Label management software is a specialized tool built to simplify the creation, tracking, and control of labels used in different industries. It helps businesses manage product labels efficiently while meeting rules and standards such as FDA, GHS, or country-specific requirements. These systems are especially useful in industries like manufacturing, logistics, food and beverage, and pharmaceuticals, where accurate labeling is essential.

Key features of label software typically include:

Design Capabilities: Tools to design custom labels with logos, product information, barcodes, and more.

Compliance Management: Built-in functionality to ensure that all labels meet regulatory standards and guidelines.

Multi-format Support: Ability to generate labels for a wide variety of products, packages, and shipping requirements.

Integration with Other Systems: Seamless integration with Enterprise Resource Planning (ERP) and Supply Chain Management (SCM) systems for smooth data flow and management.

Choosing the right label management software is not a one-size-fits-all process. The ideal solution depends on your company’s specific requirements, size, industry, and operational needs. Here are the essential criteria to consider when selecting label software:

As your business grows, your labeling needs will likely evolve. Choose brand compliance software that can scale with your business, handling increased label volumes, new product lines, or even global labeling needs.

Your label management software should seamlessly integrate with existing systems like your ERP, supply chain management (SCM), and even automated packaging lines. The easier the integration, the smoother your operations will be.

Many industries are heavily regulated, and your label management software should help ensure compliance with the necessary standards. Look for systems that offer automatic updates to comply with changing regulations, such as those set by the FDA, GHS, or local authorities.

A user-friendly interface reduces training time and the risk of errors. The software should be intuitive, allowing users to easily design, print, and track labels without requiring extensive technical expertise.

While cost is always a factor, it’s important to focus on value rather than price alone. Consider how the software can improve efficiency, reduce labeling errors, and save time, which ultimately results in a better ROI for your business.

Choosing a software solution with strong vendor support and regular updates is crucial. Ensure that the software provider offers ongoing customer service, bug fixes, and access to new features that keep your system up-to-date.

Manage packaging artwork, maintain brand consistency, and simplify compliance workflows with ease.

The right label software should do more than simply generate labels. Advanced features add significant value and contribute to overall efficiency and compliance. Here are the key features to look for in high-performing label management software:

A cloud-based system allows you to store and access label templates from anywhere, ensuring consistency and enabling remote collaboration. This also reduces the risk of losing important design files.

Automatic validation against compliance standards (e.g., GHS, FDA) helps prevent errors before labels are printed, ensuring that your labels meet legal and regulatory requirements.

Batch labeling capabilities allow you to apply labels to multiple products simultaneously, saving time and minimizing human error. This feature is particularly important for large-scale operations where efficiency is critical.

Version control ensures that the most up-to-date label designs are being used throughout the organization. It allows teams to track label revisions, ensuring that the latest designs are compliant and accurate.

Analytics features can help businesses optimize their labeling process by providing insights into printing costs, labeling errors, and time saved. This data can be used to identify inefficiencies and make informed decisions to improve operations.

When evaluating label management software, it’s helpful to compare the leading solutions in the market. Some of the top options include:

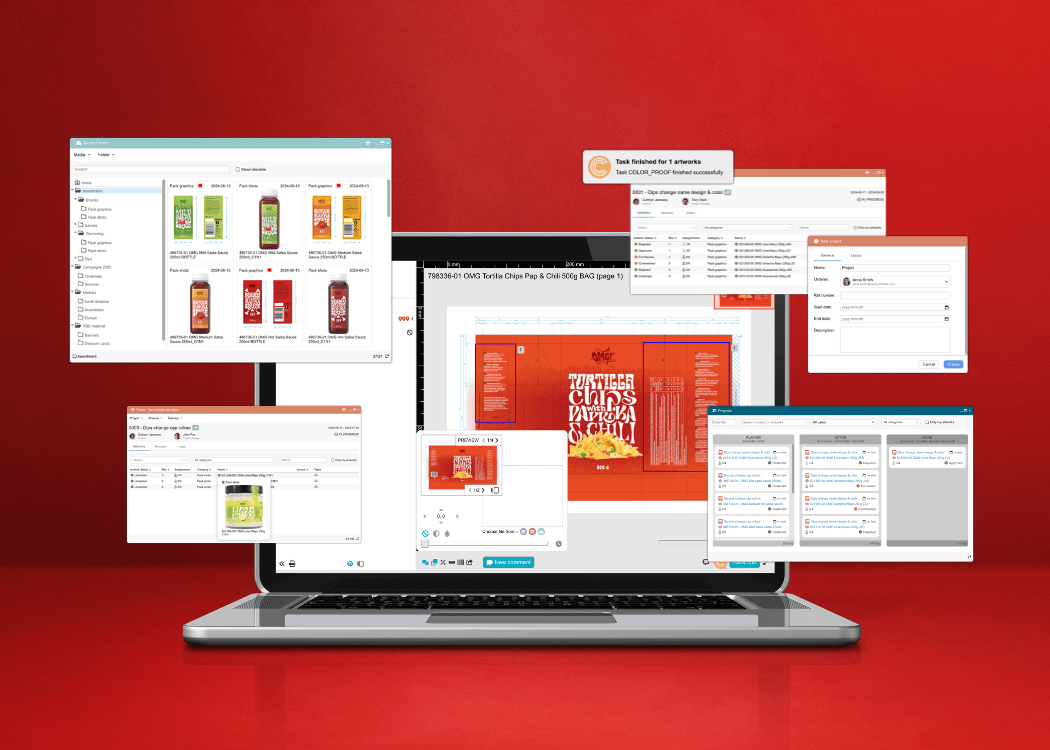

Cway is a user-friendly label management solution designed to streamline packaging processes. It simplifies workflows with automated approval processes, version control, and centralized feedback, ensuring faster project completion and fewer errors. Cway's digital asset management tools allow easy access to approved files, while its version history and approval logs help maintain compliance and full visibility.

With scalable features, Cway adapts to businesses of all sizes, offering customizable workflows and templates that grow with your operations. Secure collaboration with external partners and real-time updates ensure teams stay aligned, making Cway an ideal choice for businesses looking to optimize label management and enhance efficiency.

NiceLabel offers a scalable solution that integrates well with ERP systems. It features cloud-based label management, ensuring that users can access labels remotely and collaborate efficiently. Its compliance automation and real-time version control make it a strong choice for industries requiring high compliance standards.

Loftware provides enterprise-level solutions with extensive integration capabilities. Its platform supports label printing in multiple formats and integrates seamlessly with ERP and SCM systems. Loftware’s solution is designed for global operations, making it ideal for businesses that need to manage complex, multi-country labeling requirements.

Zebra Technologies focuses on hardware and software integration, making it ideal for companies that also require specialized labeling hardware. Their software supports high-volume printing and is well-suited for manufacturing, logistics, and retail industries.

BarTender is known for its user-friendly interface and strong automation capabilities. It’s ideal for businesses that need to create and print labels in high volumes. The software’s advanced features, such as automated batch processing and extensive template customization, make it a top contender for large organizations.

Implementing new label software can be a complex process, so it’s essential to plan carefully. Here are best practices to ensure a smooth transition

|

Best Practice |

Description |

|---|---|

|

Conduct a Pilot Test |

Conduct a pilot test with a small group of users before full implementation. |

|

Provide Comprehensive Training |

Ensure that all users are trained properly to reduce mistakes and speed up adoption. |

|

Plan for Data Migration |

Ensure that your label templates and historical data are transferred accurately to the new system. Work with your software provider to ensure a smooth migration process. |

|

Use Vendor Support |

Take full advantage of the support resources offered by your software provider. From troubleshooting to ongoing updates, strong vendor support is essential for long-term success. |

Choosing the right label management software is an important decision that affects efficiency, compliance, and overall business performance. By looking at factors like scalability, easy integration, compliance tools, and cost, companies can find a solution that fits their specific needs.

Cway software is a great choice for businesses that want to simplify their labeling processes. It offers strong features for meeting regulations, real-time version control, and smooth integration with ERP and SCM systems. With Cway, your labeling workflows stay efficient and always up to date. The platform can also scale as your business grows, making it suitable for companies of any size.

When comparing options, focus on finding a system that gives real-time visibility, maintains compliance, and works well with your existing tools. A well-chosen label management solution, like Cway, will not only make labeling easier but also help your business stay compliant and flexible as industry standards continue to change.

If you're part of a team that creates packaging—whether it’s for yoghurt tubs, medicine boxes, or shampoo bottles—you know how tricky it can be to...

For global brands, packaging is more than design — it’s a critical business operation. Every product launch demands packaging that is accurate,...

Streamline design approvals, enhance feedback loops, and get to market faster with Cway®—your all-in-one platform for artwork approval process.