Automating your compliance workflow for faster approvals

In regulated industries like food & beverage, pharmaceuticals, or cosmetics, every detail on your packaging must meet strict legal and brand...

2 min read

William Janeway

:

Updated on October 20, 2025

William Janeway

:

Updated on October 20, 2025

Brands are under increasing pressure to meet packaging compliance requirements across regions and industries. Manual tracking and updates often lead to errors and delays. That’s where compliance tools come in. In this article, we’ll look at how modern platforms like Cway® help teams automate reviews, centralize changes, and ensure full regulatory alignment.

A packaging compliance audit is a systematic review to ensure that all packaging components — artwork, labeling, materials, and processes — meet regulatory, brand, and quality standards.

In packaging, non-compliance can have serious consequences: product recalls, fines, lost shelf time, or reputational damage. That’s why manufacturers, brand owners, and suppliers often conduct regular compliance audits as part of their quality and regulatory assurance programs.

Here’s what a compliance auditor typically examines in a packaging context:

Verifying that product labeling meets all legal requirements — for example:

Ingredient listings, nutritional facts, and allergen statements (food & beverage)

Safety warnings and dosage instructions (pharma)

Recycling symbols, EPR marks, and environmental claims (FMCG and retail)

Ensuring multilingual text accuracy for regional markets.

Checking that all country-specific or industry-specific packaging rules are met (e.g., FDA 21 CFR, EU FIC, CLP/GHS, or ISO labeling standards).

Reviewing final artwork files against approved master data.

Confirming that only approved versions of designs are printed.

Ensuring text, imagery, and layout match brand and regulatory guidelines.

Checking that barcodes, dielines, and print specifications are accurate.

Auditors often require proof that every packaging change was reviewed, approved, and documented.

They check that unauthorized edits or skipped approvals didn’t occur.

Having a complete audit trail (who changed what, when, and why) is crucial.

Validation that packaging materials meet sustainability, safety, or sourcing standards.

Verification of certifications (e.g., FSC, REACH, RoHS, compostability standards).

Ensuring traceability from initial concept → artwork approval → production print.

Cross-checking that data between systems (PLM, ERP, artwork management) stays consistent.

Discover how automation and efficient workflows make every packaging compliance audit faster, smoother, and fully traceable.

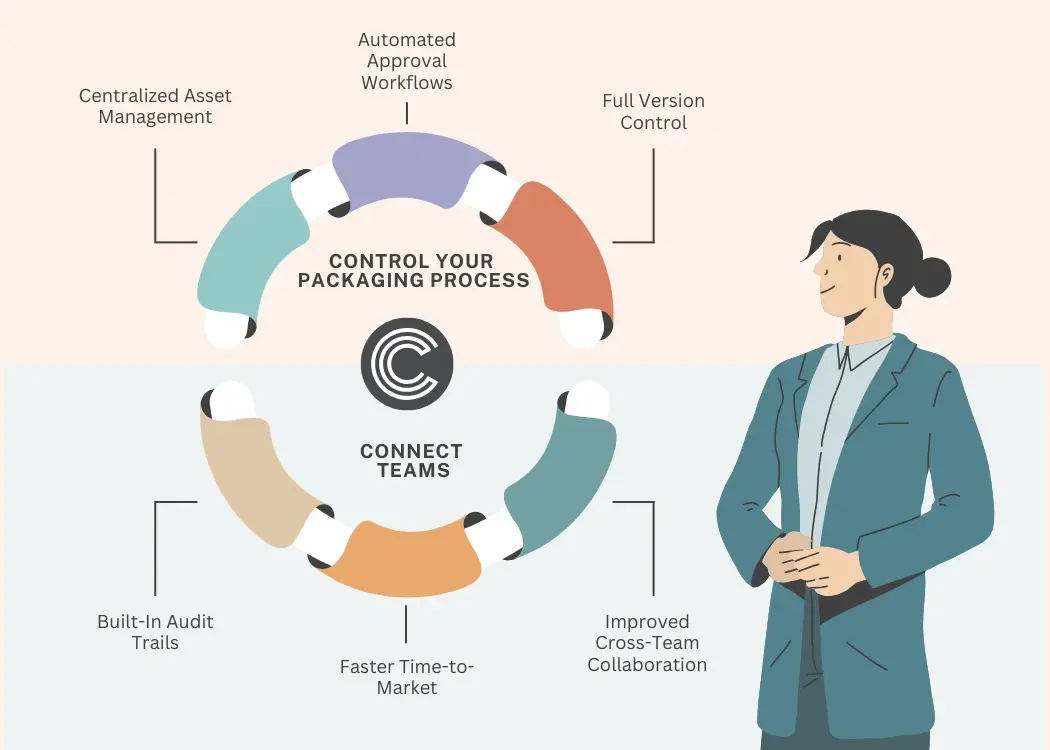

Cway’s artwork and packaging management platform is designed to make compliance audits easier, faster, and more transparent. Here’s how:

Every action in the workflow — from a label edit to a final approval — is time-stamped and attributed to a specific user. This log can be exported as evidence for auditors.

Auditors can easily review past versions, compare differences, and confirm that the approved artwork was the one sent to print.

Cway enforces multi-step approval routes with defined roles (marketing, regulatory, QA). This ensures no label is released without the required sign-offs — a critical audit requirement.

All artwork files, annotations, and proofing rounds are stored in one place, ensuring no loss of evidence. This makes it simple to demonstrate due diligence to auditors.

By maintaining a single source of truth for all packaging assets, Cway helps ensure that localized versions (different languages, regions) remain consistent and compliant.

A well-prepared packaging compliance audit is more than a formality — it’s a safeguard for your brand. By embracing digital workflows, automating compliance gates, and maintaining transparent audit trails, packaging teams can stay ahead of shifting regulations with confidence.

With Cway, compliance doesn’t slow you down — it powers your packaging success.

Get audit-ready packaging workflows

In regulated industries like food & beverage, pharmaceuticals, or cosmetics, every detail on your packaging must meet strict legal and brand...

For global brands, packaging is more than design — it’s a critical business operation. Every product launch demands packaging that is accurate,...

Is your packaging ready for 2026 compliance audits? In this article, we’ll explore what the upcoming regulations mean for your brand and how to make...