How automated artwork management transforms packaging workflows

Automated artwork management is transforming how brands, agencies, and printers manage their packaging design process. In this article, we explore...

4 min read

Ekaterina Skalatskaia

:

December 1, 2025

Ekaterina Skalatskaia

:

December 1, 2025

Is your packaging ready for 2026 compliance audits? In this article, we’ll explore what the upcoming regulations mean for your brand and how to make sure every packaging asset is compliant, traceable, and audit-ready—without the stress. Whether you're a brand manager or packaging designer, this guide will walk you through practical solutions using tools like Cway® software.

The year 2026 is shaping up to be a watershed moment for packaging compliance, driven by a confluence of regulatory tightening, sustainability mandates, and technological expectations across global markets.

Governments and industry bodies are ramping up legislation around packaging transparency, recyclability, and traceability. Key drivers include:

EU Packaging and Packaging Waste Regulation (PPWR), expected to be fully enforced by 2026, mandates that all packaging must be recyclable and clearly labeled with compositional data. Brands will be required to prove compliance through digital records.

The U.S. Food and Drug Administration (FDA) is intensifying scrutiny on label accuracy, especially for food, beverage, and pharmaceuticals, where mislabeling can lead to recalls and legal consequences.

In APAC, countries like Japan and Australia are accelerating Extended Producer Responsibility (EPR) frameworks, increasing corporate accountability for packaging lifecycle.

These shifts make 2026 a critical deadline—brands must evolve their packaging systems now or risk non-compliance, market exclusion, or reputational damage.

Inaccurate or non-compliant packaging is no longer just an internal issue—it’s a public liability. Consider this:

According to a 2024 McKinsey report, 34% of product recalls in the consumer goods sector were traced back to packaging errors, with average costs exceeding $10 million per recall.

A 2023 EU audit revealed that over 60% of inspected packaging samples failed to meet updated recycling label standards—triggering fines and supply chain disruptions.

Brands can no longer afford disconnected workflows or undocumented approvals. Without robust systems in place, they may struggle to prove compliance when audited.

Environmental compliance is also driving the change. By 2026:

All EU packaging must contain at least 65% recyclable content, and non-compliance will result in market restrictions.

Retailers are demanding full traceability of materials, often requiring brands to submit audit logs and material declarations.

Packaging isn’t just about shelf appeal anymore—it’s a data-driven asset that must align with ESG goals, circular economy principles, and global transparency expectations.

Forward-thinking companies are investing in packaging asset management platforms to ensure traceability, automate approval workflows, and stay compliant:

82% of packaging teams in a 2024 Deloitte study said they plan to implement digital proofing and asset tracking tools by 2026.

Brands using platforms like Cway® software are gaining a competitive edge by ensuring faster audit readiness, reduced risk of error, and better alignment across teams and regions.

To be audit-ready means your packaging assets are:

Centralized and traceable

Version-controlled

Approved with digital records

Easy to access for regulators or partners

Without these, audits can turn into lengthy, painful processes. And worse—non-compliance could mean costly delays or penalties.

Still managing packaging workflows via email or local folders? You’re at risk. Common pitfalls include:

Lost approvals or outdated artwork

Inconsistent labeling across regions

Inability to prove compliance on demand

These gaps can delay product launches, damage brand trust, and cost you valuable shelf space.

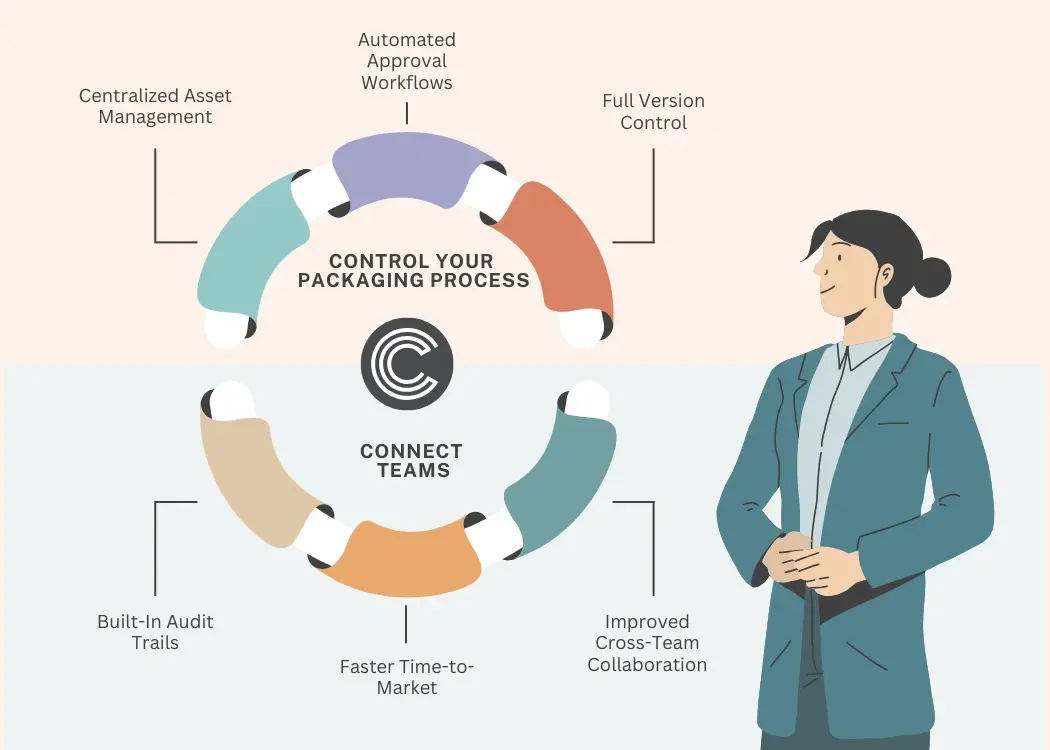

When it comes to packaging compliance, fragmented workflows, lost approvals, and inconsistent versioning are the Achilles’ heel of even the most organized teams. Cway® software is designed from the ground up to eliminate these vulnerabilities—turning packaging compliance from a reactive chore into a proactive, streamlined process.

Whether you're preparing for 2026 regulatory audits or managing a global packaging portfolio, Cway® software enables teams to maintain full control, traceability, and transparency throughout the asset lifecycle.

Here’s how Cway® platform transforms your audit readiness:

Cway® software replaces outdated folder systems and scattered tools by consolidating all packaging assets in one secure, cloud-based hub. From dielines to final artwork, every file is versioned, searchable, and accessible to the right stakeholders at the right time.

Use Case: Mills

Previously using manual workflows for CGI packaging visuals, Mills integrated their CGI requests and approvals into Cway®. The result? 2–4 weeks faster CGI delivery and 100% workflow visibility.

With Cway®, packaging approval flows are automated, structured, and digitally tracked—a huge win for audit readiness. Stakeholders are guided through tailored workflows where every sign-off, comment, and file version is logged.

Email is no longer a compliance risk.

Delays are flagged automatically.

Internal and external stakeholders collaborate in real time.

Use Case: Kavli

When adapting a Swedish product for the Norwegian market, Kavli used Cway® to manage multi-stakeholder approvals. Thanks to built-in workflows, they cut approval time by 40% and ensured every change was documented—critical for local compliance.

One of the biggest audit pain points is version confusion. Cway® ensures every file is versioned, labeled, and traceable, with easy rollbacks and side-by-side comparisons.

Teams can instantly verify which file version was approved and by whom.

Reduces errors from using outdated files.

Maintains a clean chain of custody for every pack iteration.

Use Case: Santa Maria

By switching to a structured approval flow in Cway®, Santa Maria reduced the average number of artwork revisions from 3 to 1.5—saving time and improving consistency across markets.

Cway® automatically generates comprehensive audit trails for every packaging asset. This includes:

Version histories

Approval timestamps

User activity logs

Linked reference files and comments

Whether it’s a retailer, regulatory body, or internal QA team, you can provide instant, verifiable documentation at any point in the product lifecycle.

Industry Insight:

A 2024 Cway® blog analysis found that 78% of brand managers now list digital auditability as a top operational priority—particularly in cross-border packaging and regulated industries.

When 2026 packaging regulations go live, brands will need more than good intentions—they’ll need complete, verifiable, digital control over every packaging asset. Cway® software helps you get there—faster, smarter, and without the compliance panic.

In an era where audit-readiness is mission-critical, Cway® doesn’t just support your packaging process—it future-proofs it.

1. Audit your current packaging workflows

Identify where approvals or file versions are being lost.

2. Centralize all packaging assets

Use a platform like Cway® software to store everything securely in the cloud.

3. Automate and track approvals

No more emails—every sign-off is logged digitally.

4. Train your team

Everyone from compliance to marketing should understand the process.

5. Create a 2026 readiness checklist

Ensure all future designs meet regulatory and audit requirements.

Cway®’s team works with you to tailor workflows to your real-world process, not the other way around. Their onboarding, support, and training are rated highly by enterprise clients.

📦 40% faster artwork approvals

🔁 50% fewer packaging revisions

📁 100% digital audit traceability

2026 might feel far away, but for packaging teams, the time to act is now. With Cway® platform, you’re not just reacting to compliance—you’re leading the change with a proactive, digital-first strategy that saves time, ensures quality, and builds trust with every pack.

Automated artwork management is transforming how brands, agencies, and printers manage their packaging design process. In this article, we explore...

In this article, we’ll explore how automated artwork is reshaping the way packaging assets are created and managed. Whether you're a brand manager,...

Trello is great—until your packaging project gets real.If you’ve ever tried managing a packaging design workflow with Trello or other...